Application Procedure

The Process is as follows:

- Clearing & Cleaning the Substrate:

The surface of the roof is thoroughly cleaned of all loose dirt and debris. Blisters and/or buckled areas are cut and nailed. Wet or deteriorated roofing must be completely removed. The surface is primed as needed. - Pre-application:

Remove and reset roof-mounted mechanical equipment. Replace and/or cover all skylights and install new metal flashings at new lumber skylight curbs. - Foam Application:

A blanket of insulating 1" minimum polyurethane foam is applied over the entire surface. (No maximum urethane foam thickness). - Base Coat Application:

The DURAGARD elastomeric base coat is then applied sealing the new urethane foam and providing excellent protection from the sun's damaging ultra violetrays. - Finish Coat Application:

The final coat of DURAGARD high quality acrylic elastomer topcoat is then applied. Available in White, Beige or Tan. - Final:

Final detailing and debris removal from the jobsite. A quality control final inspection takes place to ensure the highest quality workmanship and complete customer satisfaction

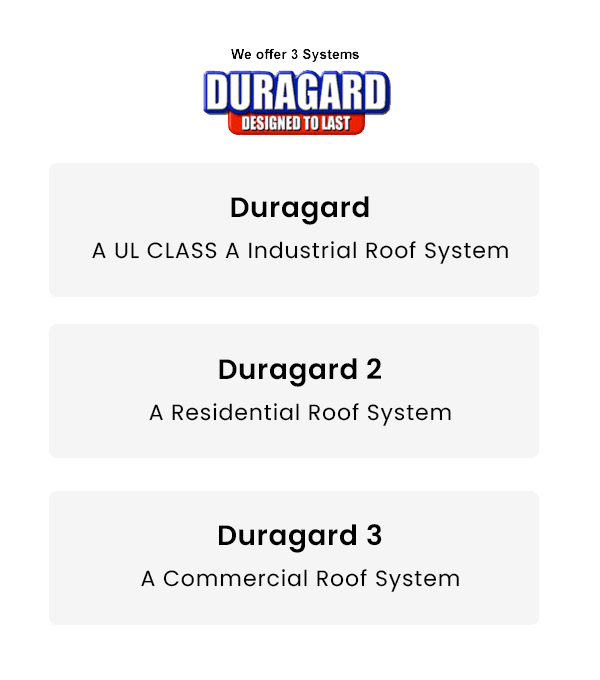

DURAGARD UL Class A Industrial Roof System (Polymer Modified White Cement Traffic Topping)

Application Procedure

- Spray-in-Place Insulation Procedure: Urethane foam insulation consists of a two-component sprayable type specifically manufactured for roof insulation.

- Apply insulation to all low and/or ponding areas to reduce standing water.

- Spray-apply 1", 2.5 - 3 lb density urethane foam over all roof areas to waterproof and insulate the roof substrate. Insulation shall be carried up all adjacent vertical surfaces to waterproof all penetrations and roof-to-wall junctures. Additional foam insulation may be applied to taper and enhance drainage and/or to provide greater R-value.

- Fluid Applied Waterproofing

- Apply DURAGARD acrylic elastomer base coat at the rate of 1-1/2 gal/100sf.

- Apply DURAGARD acrylic elastomer second coat at the rate of 1-1/2 gal/100sf.

- Apply DURAGARD acrylic elastomer top coat at the rate of 1-1/4 gal/100sf to all vertical surfaces.

- Terminate coating application 4" above foam termination.

- Apply Shasta #6 roofing granules onto an uncured second coat at the rate of 60 lbs/100sf.

- Apply DURAGARD C-Cure modified cementitious roof coating into embedded aggregate at average of ¼" thickness to provide a 100% foot traffic resistant hard cement shell surface.

DURAGARD 2 Residential Roof System

- Spray-in Place Insulation Procedure: Urethane foam insulation consists of a two-component sprayable type specifically manufactured for roof insulation.

- Apply insulation to all low and/or ponding areas to reduce standing water.

- Spray-apply 1", 2.5 - 3 lb. density urethane foam over all roof areas to waterproof and insulate the roof substrate. Insulation shall be carried up all adjacent vertical surfaces to waterproof all penetrations and roof-to-wall junctures. Additional foam insulation may be applied to taper and enhance drainage and/or to provide greater R-value.

- Fluid Applied Waterproofing

- Apply DURAGARD acrylic elastomer base coat at the rate of 1-1/2 gal/100sf.

- Apply DURAGARD acrylic elastomer top coat at the rate of 1-1/2 gal/100sf using a white, tan, or gray color.

DURAGARD 3 Commercial Roof System in Phoenix, Arizona

- Spray-in Place Insulation Procedure: Urethane foam insulation consists of a two-component, sprayable type specifically manufactured for roof insulation.

- Apply insulation to all low and/or ponding areas to reduce standing water.

- Spray-apply 1", 2.5 - 3 lb density urethane foam over all roof areas to waterproof and insulate the roof substrate. Insulation shall be carried up all adjacent vertical surfaces to waterproof all penetrations and roof-to-wall junctures. Additional foam insulation may be applied to taper and enhance drainage and/or to provide greater R-value.

- Fluid Applied Waterproofing

- Apply DURAGARD acrylic elastomer base coat over insulation at a rate of 1-1/4 gal/100sf.

- Apply DURAGARD acrylic elastomer second coat at the rate of 1-1/4 gal/100sf.

- Apply DURAGARD acrylic elastomer third coat at the rate of 1-1/4 gal/100sf using a white color.

NOTE: These systems possess a high strength-to-weight ratio, weighing approximately 70% less than a comparable asphalt roof. It locks the roof deck together with a monolithic barrier to heat and moisture. It is adaptable to any configuration upon which it is sprayed.

FREQUENTLY ASKED QUESTIONS

Contact Info

To learn more about our services, call us at (602) 866-2703.

Whatever you need, we promise to deliver and exceed your expectations.